Knowledge of several critical environmental impact areas of aquafeeds is essential in helping make sustainable decisions. That is why some BioMar feeds in our Europe, Middle East & Africa (EMEA) Divisions will now include new sustainability indicators on technical product datasheets. This knowledge will help farmers in their pursuit to reduce negative environmental impacts.

In their 2020 Global Sustainability Report, BioMar announced its 2030 ambitions for more sustainable aquaculture feeds. The new targets adopt a deeper level of understanding towards sustainability approaches, such as circular and restorative levels of raw materials. These are a set of new indicators developed to drive sustainability and decouple feed supply chains from food for human consumption.

Our three ambitions take a holistic approach to sustainability and show that BioMar takes responsibility and leadership in the sustainable development of the industry. The ambitions have been transformed into innovative low-impact feed solutions with the intention of helping farmers on their blue journey towards increased sustainability.

Avoiding problem shifting

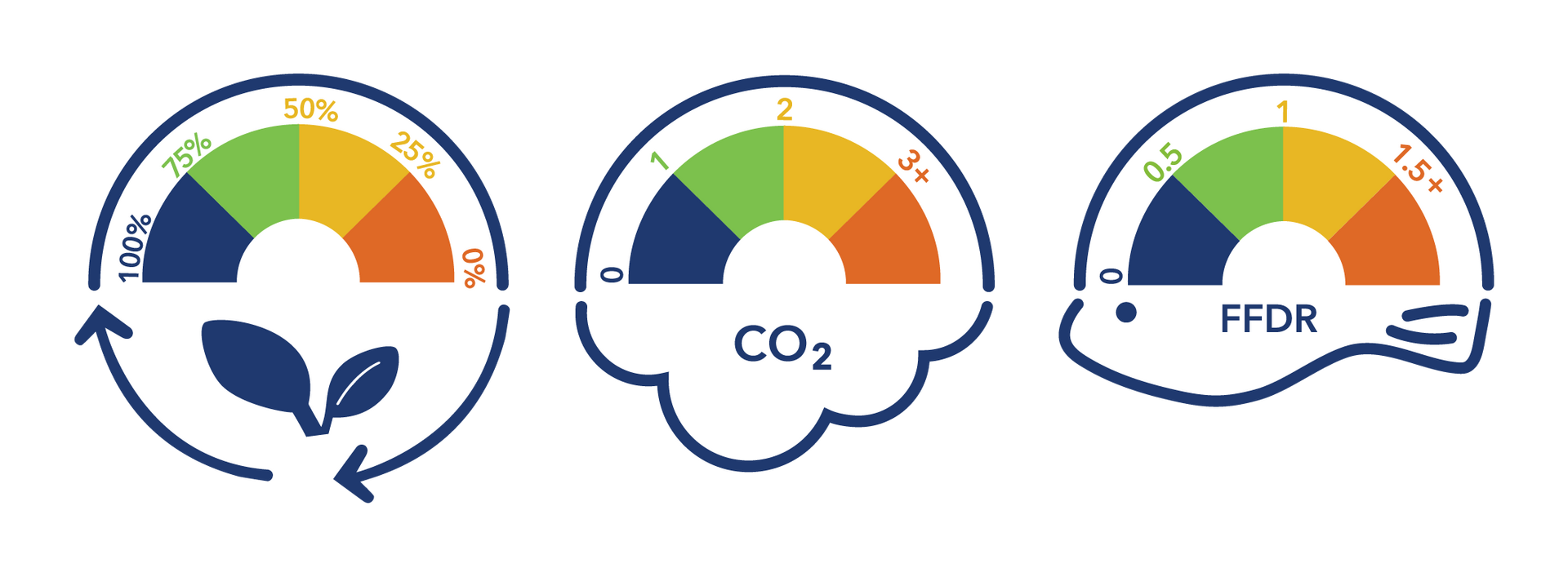

The upcoming sustainability indicators included on technical product datasheets focus on carbon footprint, the level of circular and restorative feed ingredients and the FFDR of the feed.

“There is a substantial focus on climate action and the reduction of greenhouse gasses (GHG), which is justified and something we take very seriously at BioMar. However, sustainability is not only about reducing our carbon footprint. Other impacts need to be considered as well if we want to advance the aquaculture industry”, explains Vidar Gundersen, Global Sustainability Director at BioMar.

“We believe in a well-balanced planet. To avoid problem-shifting, it is essential to assess potential solutions using best-in-class science-based sustainability. By using a broader range of metrics allows for a more balanced and holistic approach to our efforts”, Vidar Gundersen continues.

“As we strive to minimize negative impacts and mitigate risk, we are encouraging improvements in our supply chain. We want to incentivize regenerative and restorative practices, and one way we can do this is by setting targets for minimum inclusion levels of circular and restorative ingredients”, Vidar Gundersen adds.

Science-based methodology

Sustainable steering of the value chain, life cycle assessments (LCA) and material flow analysis allow BioMar to calculate impacts on both a company level and on individual product types. Calculations at the feed level give our farmers a preference based on feed performance, price and now sustainability indicators.

The measurement of our feeds on environmental impact parameters are all founded on science-based methodology and analyses made by our BioSustainTM LCA tool. “These are highly complex matters. It is important for us to work with accurate data and robust scientific methodologies and that is why our highly skilled sustainability scientists who are experts in their fields, have incorporated these in our tools”, says Vidar Gundersen.

The blue journey

“Access to accurate and a wide variety of information are crucial for taking the right steps in our blue journey. We believe by including sustainability information on our technical datasheets will provide our farmers with an increased understanding that will assist in their decision-making”, Vidar Gundersen explains.

“BioMar has been leading the sustainability movement in our industry. It was a game changer when, decades ago, we started declaring phosphorus and nitrogen discharge from BioMar diets on our data sheets. Now, with these sustainability indicators available on our technical datasheets, the farmers are guided in their pursuit of reducing negative environmental impacts. We invite our farmers to join our blue journey,” Gundersen concludes.

The upgraded information with sustainability indicators will be applied to the technical datasheets of product groups, such as Blue IMPACT, Salvea and a selected number of EFICO products, provided by production facilities in the EMEA business units.

Read the full story and read more about BioMar's sustainability initiatives in our 2023 Sustainability Report.